|

We get calls every day to create pieces of stainless tubing with certain dimensions and bends. Until now, everything had to be quoted case by case. We hope this configuration tool helps automate the process a bit. First, we have 304 welded tubing in sizes ranging from 1/4" OD all the way up to 5/8" OD and we have the ability make clean bends up to 180 degrees. Keep in mind that as the tubing OD goes up, the bend radius does as well (see note below).

Granted, the options on this item are lengthy and a little confusing so read this first. The price listed above is a base price that is affected by tube diameter, overall length, and number of bends. Each inch of length adds cost. Each bend adds cost. Smaller diameter tubing is a little cheaper than larger tubing.

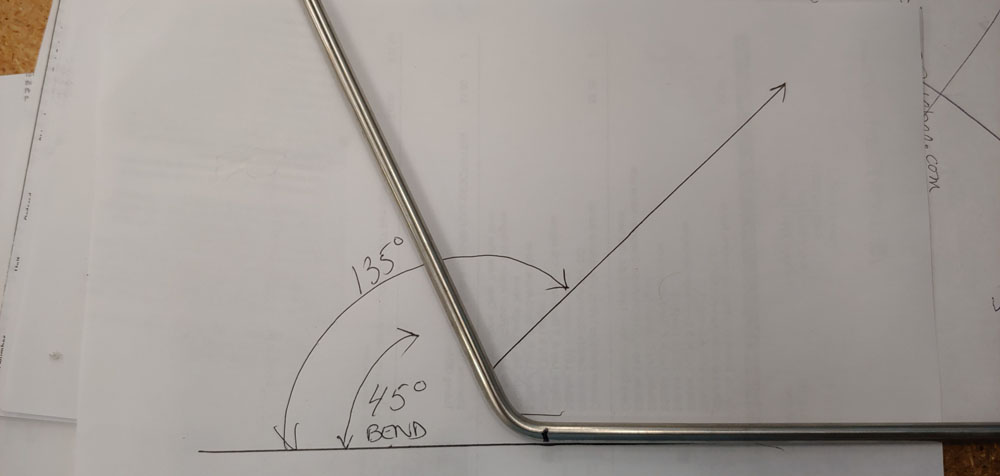

This current version of the configuration tool is able to specify up to a 3-leg tube with two bends. You pick the lengths of the legs and the angles of the bends. The most important thing to know is that we use BEND ANGLE specification which means how much we bend from straight. If we take a piece of tubing that is straight and force it to a bend angle of 45 degrees, the angle between the two resulting legs will measure 135 degrees actual (an obtuse angle). More angle examples below to help you understand. A bend angle of 135 will make a Pac-Man mouth shape. A bend angle of 180 is like the top of a shepherd's hook.

Complicated pieces:

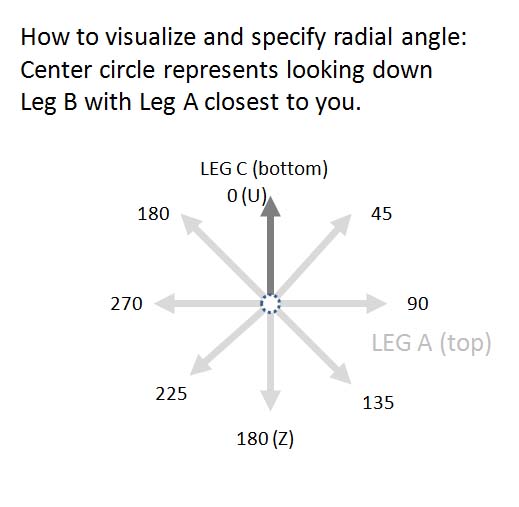

If you specify three legs, you must specify two bends. When you do that, you end up with a relationship between the direction of leg A and the direction of Leg C. We call that a radial angle. If you look at the picture below, the center dotted circle represents Leg B as if you could look straight down through the center. The dark grey arrow represents Leg C far away from you and the light grey arrows represent leg A nearest to you. If you set the radial angle drop down to 0 degrees, the resulting A, B, and C would look like a "U" shape assuming 90 degree bend angles. If you set radial to 180 degrees, you'll get a Z shape.

Some examples to further help. Let's say you want to build a portable whirlpool arm that will spin the wort counterclockwise. You'll want leg C to point to your right, then leg B gets you up to the top of the pot. Leg A is the feed in for the wort so you'd want that bend to be a little more than 90 (about 120 degrees) and the radial angle should be 90 degrees so that it stick away from the pot perpendicularly. So, a typical whirlpool would be Leg A 3" with 135d bend, Leg B 18" with a 90d bend. Leg C 3" and a radial bend of 90 or 270 depending on which direction you want the wort to spin.

If there's something you're thinking of that can't be done with these dropdown options, give us a call.

To replicate what we offer for a simple 24" long racking cane it would be Leg A = 4", A bend angle = 90, Leg B = 24", none, none.

How about just a straight piece of tubing? No problem. Set everything to none except for Leg B length, which you'd simply set to your desired tube length. If you want a straight length longer than leg B allows, you can add a Leg A length but still leave the bend at NONE.

Tube End Options:

Currently all tube end options include having us TIG welding a type of fitting to the end. This option may add a few extra days to the handling time of your entire order so please anticipate that.

Simple male NPT threaded ends allow you to thread any kind of female npt threaded fittings on.

The male camlock and BLQD fitting option allows you to connect the female QD of those respective systems to the tubing. Details about the camlocks are here and BLQDs are here.

Lastly, we can also put triclover flanges on the end of the tubing by drilling a center hole in a blank cap. We're willing to weld just about anything that we stock to the end of the tubing but that will require a quote.

Due to customer demand, we've added the option to weld a fitting to both ends of your tubing contraption. One dropdown specifies the leg A end weld and the other dropdown is for the "other" end, currently labeled B or C leg because it really just depends on if you are building a simple or complex tube. If you are simply ordering a STRAIGHT piece of tubing and you want a fitting on one end, we don't care which dropdown you use for the welded fitting. If you want BOTH ends of the straight piece to have welded fittings, use the both dropdowns even if you specified the length only the the B - Leg length dropdown. Sorry if this sounds confusing. If you need help, just email or call.

Bend Radius Constraints! Please understand that our ability to make short legs is limited by the fixed bender radii.

5/8" tubing - Our bender has a 2-3/8" radius. That means if you specify a bend of 90 degrees, the adjacent legs must both be at least 3" to ensure that we're on a straight area and not on the curve. If this is hard to understand, try this; If we bend 180 degrees to create a hairpin, the centers of the two legs will be a minimum of 4-3/4" apart.

1/2" tubing - This radius is fixed at 1-1/2" so the minimum leg length would be 2" since we don't cut in half inch increments.

3/8" tubing - Fixed radius of 1". You could have a leg as short at 1" but we may cut it at 1-1/4" to let the cutting tool ride on a straight section.

1/4" tubing - Fixed radius of 5/8", also a minimum leg length of 1".

If you specify a leg length shorter than the minimums listed above, we can do it but the open end at that cut is not going to be a perfect circle and it will not lock into a compression fitting. If that short end is just facing the bottom of a pot, no problem.

Please be aware that the legs are measured to the centerline of the bend. If the angle is 90 degrees, the measurement is essentially to the centerline of the adjacent leg. If this is confusing, you can email us a quick sketch of what you want to do and we will advise how to enter it into the dropdown selections.

THIS PRODUCT WILL ADD A FEW EXTRA HANDLING DAYS TO YOUR ORDER WHETHER WE ARE WELDING ONTO IT OR NOT. We have several picker/packers but only a limited portion of our staff is involved in bending and welding.

We are NOT interested in supplying your business with large quantities of custom tube bends. There are companies that specialize in production quantities of bent tubes with a very high level of precision. We are not one of them. We have a quantity limit of 5 on this item.

|

|

|

Custom tubing

Custom tubing