BrewHardware.com heating elements are 100% stainless steel from the the tubular sheath down to the hex and threaded bushing part. They do not have the same problems with the screw in base rusting such as the elements found on Amazon and in the home improvement stores. Understand that all stainless elements cost more but you will fully appreciate the longevity of stainless steel. Don't buy elements twice. Get these the first time.

|

|

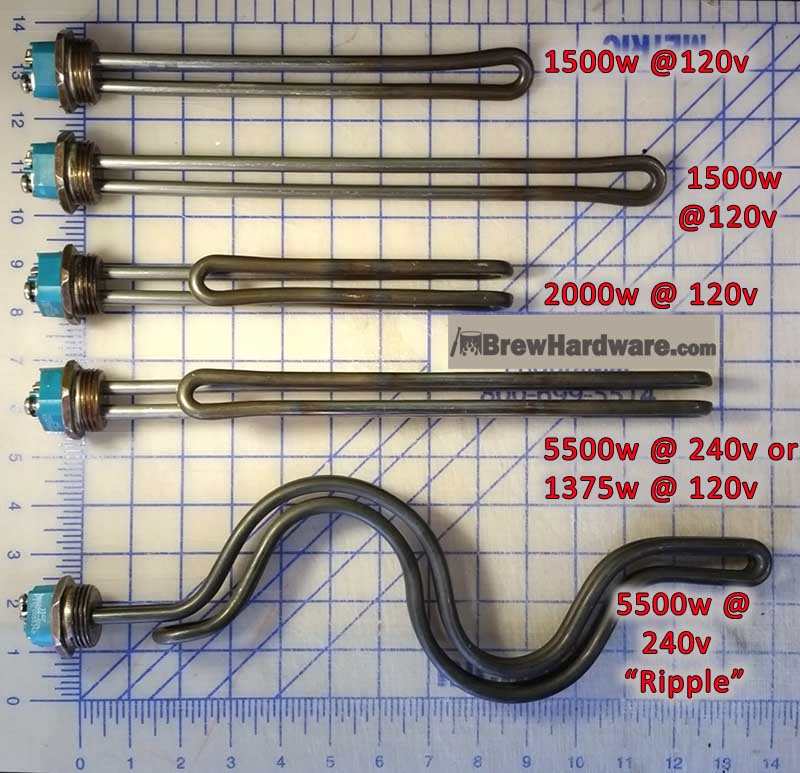

Due to customer inquiry and popular request, we have been expanding our selection of element configurations.

The specs you need to be aware of are the supply voltage, effective wattage, element length, and resulting watt density. The element length is important for direct installs into the side wall of your kettles and for use with our Hot Rod heat stick. Measure your pot diameter and make sure the element will physically fit (the Hot Rod adds 2.5" of depth).

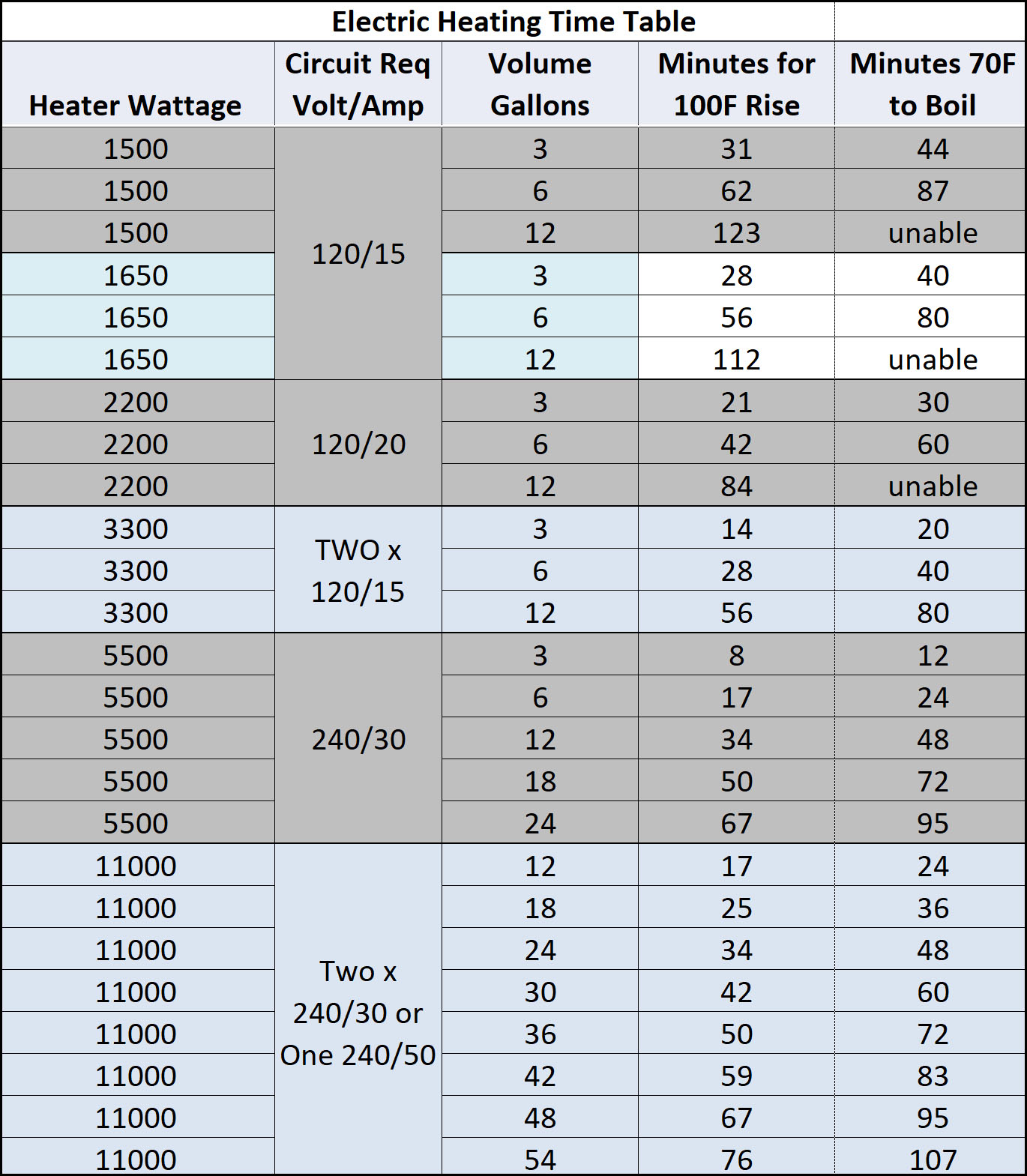

The required wattage for brewing operations will vary with batch size and while we can make recommendations, it's impossible to anticipate all variables. When heating water only, the wattage will only affect how long it takes to reach your target temperature. In that case, more wattage is always better as it cuts brew day time. These wattage requirements can be reduced a bit if you insulate the kettle. Keep in mind that everyone's impression of "boiling" is a little different. We've created this chart to help you decide what element wattage will work for what you want to do. In some cases, you may not have the electrical circuit capability to brew electric at the batch size you're looking to make.

Watt Density is relatively important when the element is in direct contact with wort, whether in the mashing process or in the boil. Watt density is expresses as generated watts per square inch of element surface area. It effectively dictates how hot the surface of the element can get. The lower the watt density, the less likely it will scorch the sugar (or protein) in the wort. For a given wattage, watt density is reduced by adding length. To further lengthen while keep overall element length reasonable, the tubing will be folded back onto itself. These are known as foldback elements and typically fall into Low Watt Density or Ultra Low Watt Density designations. On higher watt elements such as 4500 and 5500 watt, density is further reduced by making a set of serpentine bends as seen in the picture below. These are often called "ripple" elements and despite the high wattage, it is the lowest watt density you can use in your boil kettle short of installing multiple lower watt elements in series. One other trick to reducing density is using a 240 volt rated element and powering it with only 120 volts. The effective wattage, and watt density, is reduced to 25% of the rated 240 wattage. For example, our straight 5500 watt foldback element is approximately 120 watts per square inch. Running it on 120 volts gives you 1375 watts total at only 30 watts per square inch for ILWD (Insanely Low Watt Density). Please keep in mind that specification of "Ultra Low Watt Density" or any of the other names are not dictated by some industry standard, at least not that we are aware of, but you will see a lot of claims about what "Watt Per Inch" densities fall into what category. Consider this full transparency that we don't know where these names come from and that we don't know exactly which WPI numbers mean anything specific. When in doubt, lower densities are always better than higher ones as long as the heater is making the wattage that you need for the job. We regularly use 5500 foldback and ripple elements to boil wort and have not had any scorching issues other than the one time we emptied the pot without turning off the element (don't do that).

Note we have more elements available than the ones in the picture below.

|

Element Type

|

Density at Voltage Used

|

|

|

240

|

120v

|

|

1500w Short

|

X

|

70 WPI

|

|

1500w Long

|

X

|

52 WPI

|

|

2000w Foldback

|

X

|

60 WPI

|

|

5500w Foldback

|

120 WPI

|

30 WPI (only 1375 total watts)

|

|

5500w Ripple

|

60-75 WPI

|

15 WPI (only 1375 total watts)

|

|

|

|